-

Posts

6,098 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Classifieds

Tip Site Directory

Blogs

Articles

News

Arborist Reviews

Arbtalk Knot Guide

Gallery

Store

Freelancers directory

Everything posted by Rob D

-

Yep and please let us know it all works to satisfaction as you're a pretty regular 2511 man.

-

I think it is just saying the sprockets are replaceable. But I've never known any one to replace one in a laminated bar - either it has failed too early and is more a warranty thing - or the bar will be well and truly worn out... and then not worth replacing a failed sprocket.

-

Yep they will fit fine - but keep half an eye on how it transitions round the drive sprocket as the T525 is more of an unknown. Put your findings on how you have found the bar up on here (as well as any pics!).

-

Thanks Darrin Quality wise they are something an unknown! I have used one a few times and they seem really good or at least no issues. We will of course back them if there are issues. Really the main selling points are - they all take 56 drive links of Stihl 71PM3, they look pretty cool, they are a dedicated bar mount to the saw they fit. Change to 1/4 drive sprocket and you can also fit to pole saws. The service from the manufacturer (which we don't want to disclose but they have many years in the business) has been almost too good to be true! So now it's fingers crossed and hope you lot like 'em! Compared to Sugi - I don't think that any bars last as long as a Sugi bars in the right hands. But that rail hardness can come at a price in terms of they can chip more easily. These should last better than others out there but only time will tell...

-

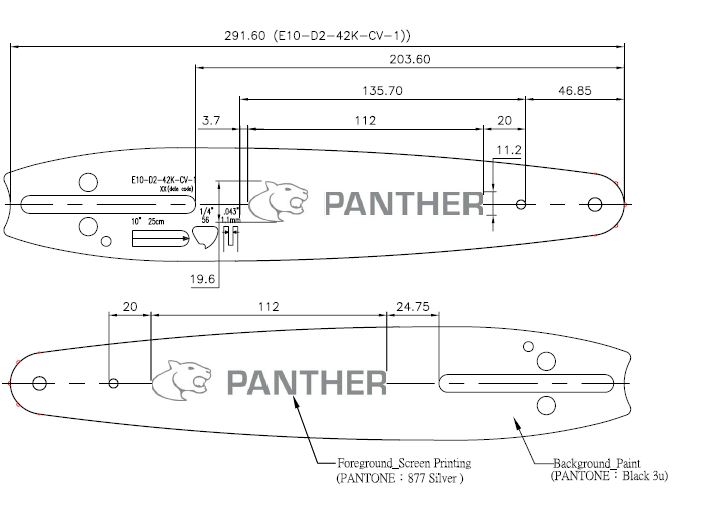

The new Panther Mini bars are now in - £28-00+vat each. We've them in dedicated mounts to fit the saws as listed and they all take 56 drive links of the 1/4 picco Stihl chain. Find them here https://www.chainsawbars.co.uk/?s=panther+mini&submit=Search&post_type=product Hopefully this should now open up this unique chain to Husky users, give Stihl MS150T folk another option and Echo 2511 people less of a headache figuring out which size chain they need! £28-00+vat each.

-

Yep - this is a very common bar - you could use either BC2M-8J37-A for the pro lam version or BC3T-8J37-A for the pro solid version. https://www.chainsawbars.co.uk/product/sugi-pro-lam-15-325-058-64-drive-links-husq/ https://www.chainsawbars.co.uk/product/sugihara-15-325-058-64-drive-links-husq/ These are the same mount and same chain spec as that Oregon bar you have there.

-

We are making a few changes to how we do things. Currently we run x4 websites with the x3 main retail sites being www.alaskanmill.co.uk, www.sugiharabarsuk.co.uk, and www.chainsawbars.co.uk But as we have got busier and stock more products it has been harder to keep on top of stock control. Also there are issues when a customer wants a product of one website and has an account on there but something else he/she wants is on another website! Loyalty points do not cross over and have to be transferred manually as well... the startings of chaos ensue! So to make things more efficient we are going to make www.alaskanmill.co.uk and www.sugiharabarsuk.co.uk info sites only. All products are on CSB website and then that's that - one site to update, manage and take orders on. Hopefully this works for us and for you. You can still use the other sites as points of reference and also we will keep info on loyalty points etc for 6 months so when you next place an order with us we can put these onto your account. Here is a copy of the newsletter we sent out - any questions put them here or e-mail. To find products quickly on CSB and save searching you can always type in the SEARCH PRODUCTS box at the top of the page. The Alaskan Mill and Sugihara UK websites are changing. Due to our growing dealer network these websites will become a buyers guide for Alaskan Mills and Sugihara rather than a full e-commerce site. This will happen on or after 11th May, 2018 Why The Change? All products on these websites can currently be purchased at our sister website www.chainsawbars.co.uk. Running three websites causes issues in maintenance and performance. By amalgamating them this will: Improve stock control Amalgamate loyalty points Improve customer service Improve delivery times What Does This Mean For Me? All orders can be placed on the www.chainsawbars.co.uk website going forward. Loyalty Points - we have a record of all loyalty points so to transfer them simply place your next order on the www.chainsawbars.co.uk website. We will then either refund off that order or add your points to your account on Chainsawbars. We will keep a record of all Loyalty Points from Alaskan Mill and Sugihara for 6 months from 11 May 2018. To ensure you do not lose your points, please place an order or contact us within this timescale. Please note all products can be bought on www.chainsawbars.co.uk website. If you are looking for a specific bar simply type the part number into the SEARCH PRODUCTS box: This is a positive change and one which we hope you will find beneficial. If you have any queries or wish to contact us about the changes, please email us at [email protected]

- 1 reply

-

- 4

-

-

We don't tend to do Husky bars and tips... but sure Jonsie will have them. Here's a vid on how to change them over.

-

We will very shortly have our new Panther Mini bars in so you can run the Stihl 3670-71PM3 1/4 .043 chain on the Husky T525, T536Li XP, MS150T, MS150, MSA160T and Echo CS-2511TES. These are all dedicated bars for the specific saws and all run 56 drive links of the Stihl chain - the idea being to simplify things so that all the 10" bars for these little saws run the same drive link count of the same chain. *NB on the Husky T536Li XP and 536Li XP you will need to change the drive sprocket from 3/8 lo pro to 1/4 https://www.chainsawbars.co.uk/product/husqvarna-14-sprocket-for-536li/ For the Stihl bar go here https://www.chainsawbars.co.uk/product/e10-j1-42k-cv-1-10-panther-mini-echo-cs-2511tes-1-4-043-56-drive-links-expected-20th-may-2018/ For the Husky bar go here https://www.chainsawbars.co.uk/product/e10-d2-42k-cv-1-10-panther-mini-husky-525-536li-t536li-xp-1-4-043-56-drive-links-expected-20th-may-2018-copy/ For the Echo bar go here https://www.chainsawbars.co.uk/product/30050083403-stihl-rollamatic-e-mini-10-14-043-57-drive-links/ They look pretty snazzy. I've tested one for a month or two but I'm not doing the sort of hours cutting that someone full time on the tools does... we don't have them yet but you can pre order online.

-

Going large with a Panther Mill! Another custom double ended set up.

Rob D replied to Rob D's topic in Chainsawbars

Sure you are correct Rob, when I used a 076 which is a chugger and the 084 when we paused milling and I let go of the throttle on the 076 often the revs didn't go down at all and it sounded like it was screaming. It was very hard to tell what was going on tbh as it's all pretty loud! I ended up feeling it was prob safest to pair similar saws....i.e I would be happier with a 660 and 084 or 2x 076/ 075 /090 /051 etcs Yep - it really still all comes down to what works best for you and there are no hard and fast rules. There are so many variables involved makes it impossible to say exactly what is right and wrong. I can only say from using really varied saws it all seemed to work pretty well. I was thinking of getting a double ended bar to run the K095 mount which would allow people to use the smaller Huskys and/or the cheap 62cc saws off ebay to mill. You could then have a pretty cheap setup capable of milling big timber! In theory...- 12 replies

-

- chainsaw milling

- double ended bar

- (and 5 more)

-

Environmentally friendly packaging - good idea or just looks bad.

Rob D replied to Rob D's topic in Chainsawbars

Yes but the shavings we have will not be like these you are describing! They will make a mess and they will be dusty! -

Going large with a Panther Mill! Another custom double ended set up.

Rob D replied to Rob D's topic in Chainsawbars

I have tried loads of set ups with loads of different combos - and for my pennys worth it comes down to this. If you ran them full tilt out of the wood one saw (the faster) would drive the other. But once buried in the wood both saws revs come down. Say an MS880 max revs is 9000. Say an MS660 max revs is 11000. Start cutting with these and the revs of both fall to 6000. So both are trying to push that chain around... it's not really relevant whether they rev higher than each other unladen as long as when cutting the revs on both are below their max revs. More info here if you need it:- 12 replies

-

- chainsaw milling

- double ended bar

- (and 5 more)

-

Going large with a Panther Mill! Another custom double ended set up.

Rob D replied to Rob D's topic in Chainsawbars

- 12 replies

-

- 1

-

-

- chainsaw milling

- double ended bar

- (and 5 more)

-

The little Panthers seem better - nose sprocket seems better fitting tolerance and they seem a little stiffer - but really only time will tell. I've been using one on an Echo 2511and seems fine.

-

We should have some of the 1/4 .043 bars for this Husky - would be great if someone could double check the Stihl 1/4 .043 chain travels smoothly around the Husky 1/4 drive sprocket (but if it is driving 1/4 .050 it should do). In fact we will have dedicated 10" bars running the 1/4 .043 - one for this Husky and the 536Li/Stihl 150T/Echo2511 all taking 56 drive links of the Stihl 3670-71PM3 1/4 .043 chain (but all different bars particular to that saw). Had enough of all the different drive link counts and this chain not fitting on this bar hence we have got these made somewhere else... hope they are good!

-

Really the hyperskip is good for over 4 foot bars - under that and a big powerhead you may as well use full comp. But it is mad how it smoothes out the cut - push hard and the saw just keeps it's revs and does not bog down. It is very user friendly. Lo pro can stretch more, less stay sharp and more stretch - but it does give a lovely fine cut particularly the Stihl PMX.

- 6 replies

-

- 2

-

-

- chainsaw milling

- chainsaw mill

- (and 6 more)

-

Yep I have that and it is a good read. Lo pro set ups are around 8mm kerf - so you save 20% over .404 but of course you do have the disadvantages of lo pro. Have you tried the 27RX yet? That is crazy chain on a larger set up - only a few teeth to sharpen and so smooth to cut with.

- 6 replies

-

- 1

-

-

- chainsaw milling

- chainsaw mill

- (and 6 more)

-

We are starting to make a few custom double ended set ups now - these are not production ready as such and things like bar drilling and the nose end need tweaking but once up and running they seem to work well. This is Scott in Devon going from a smaller Panther up to a 72" double ended version MS880 one end and MS660 on the other.

- 12 replies

-

- 4

-

-

- chainsaw milling

- double ended bar

- (and 5 more)

-

Panther chainsaw milling - post your feedback and pics here :)

Rob D replied to Rob D's topic in Panther Mill UK

Could you drill an access hole in the skid to come into the tensioner that way on those older saws? Also having trouble tracking your address can you PM it over to me? Thanks for letting us use the vids and keep any feedback good or bad coming please. -

Haha! Yep as said really find what works best for you and stick with that - very hard in someways as folk are always asking for 'what the best' is (for everything not just ripping chain). But there is no best!

- 6 replies

-

- 1

-

-

- chainsaw milling

- chainsaw mill

- (and 6 more)

-

Panther chainsaw milling - post your feedback and pics here :)

Rob D replied to Rob D's topic in Panther Mill UK

Great vid - like the way you held off the nearside saw to keep the mill in the middle of the first cut rails. I reckon that is the Oregon 27RX Hyperskip that allows this - a full comp chain I think there would be no fighting it! I'd like to use the vid for a bit of marketing purposes if ok? If so happy to donate a couple of smaller stainless brackets so you can brace your first cut system in the middle rather than needing wedges. Will send a PM as well. -

Panther chainsaw milling - post your feedback and pics here :)

Rob D replied to Rob D's topic in Panther Mill UK

Sorry late reply Mark - the parts are not interchangable between the two I'm afraid.. -

Made this page on ripping chain which is something I've been meaning to do for years but never got round to it. Mainly all the questions on ripping chain tend to be the same so hopefully this covers the subject pretty comprehensively - however if there is anything missing or not answered please post and I'll add it in. It's copied and pasted from the CSB website so not sure if the links will work or not. Chainsaw ripping chain comes in several different sizes so please select your chain from the options below: . .404 .063 Ripping Chains 3/8 Ripping Chains .325 Ripping Chains 3/8 lo pro Ripping Chains . . Ripping chain is chainsaw chain designed specifically for cutting with the grain. Ripping chain is always micro chisel or semi chisel chain which features a re configured cutting angle of 10 degrees. . With Oregon and Stihl ripping chain this is the only difference - the chain is not made differently or any different from 'normal' chain. Only the cutting angle is different. Granberg ripping chain has been modified further - this configuration features x2 scoring cutters followed by x2 clearing cutters. The easiest way to sharpen this is by making all the cutters 10 degrees however if you wish you can sharpen the scoring cutters to 20 degrees and the clearing cutters to 5 degrees. Please bear in mind this process is carried out manually on a grinding machine at the factory and so some of the scoring cutters can become hardened in the process. This makes them very hard to sharpen using a round file and some sort of grinder may be required. . [caption id="attachment_19422" align="aligncenter" width="500"] Idenitfy Parts Of The Chain[/caption] . You need Ripping Chain to work with a chainsaw mill. It is dangerous to use ripping chain for ordinary cross cutting purposes as kick back could be more violent. . FAQS on Ripping Chain Can I simply adapt my existing chain to become a 'ripping chain'. Yes you can but only if it is of the chisel or micro chisel variety. If you are not sure what type of chain you have then first job is to identify it. You can ID exactly which chain you have using our Essential Info pages here and the Chain ID table found here. Now you know what make and size chain you have look down the chain at the outer profile - check the pictures below of the Oregon 27R and Stihl 46RCX). Does your chain profile look similar to this? If so it is micro or semi chisel chain. If you have semi or micro chisel chain you can alter the angle from 30 degrees to 10 degrees. Chisel chain has a very right angled appearance while micro or semi chisel chain as a more rounded appearance. Remember chisel chain is no use to convert into ripping chain. Check the end profile and confirm if you have chisel chain - it will look something like the below picture. What happens if I use chisel chain or 'ordinary' cross cut chain to rip timber? You can use it for one or two jobs but it is not recommended. You will find the vibration is a lot higher and the quality of the surface a lot rougher than if you used dedicated ripping chain. The harder the wood the more pf these issues make themselves felt. Skip link and hyper skip link ripping chain - pros and cons For longer bars (bars that are over 3 foot) you may consider using skip link chain on your chainsaw mill. Skip link chain has an extra tie strap between each cutter. This means there are less cutters taking 'bites' out of the wood, more space for chip waste to be expelled from the cut and less resistance on the chain so chain speed is kept up. So why doesn't everyone use it all the time? Because if you have a shorter bar and plenty of power you have less teeth cutting and so your cut will actually be slower and rougher than full comp chain. So it only starts coming into it's own as bars become longer. What chain sizes are available? There are now very few chains available in full skip that are micro chisel - you have Oregon 27AX which is full skip chain in 30 degree cross cut format. So you would have to alter the angle of this from 30 degrees to 10 degrees to make a skip link ripping chain. The other option is Oregon 27RX. This is known as hyperskip ripping chain with x10 tie straps between each pair of cutting teeth! This comes pre sharpened to 10 degrees. Lo pro ripping chain - pros and cons Similar to skip link chain 3/8 lo pro ripping chain is not for everyone. However most chainsaw millers are always looking out for a longer bar to go on their existing chainsaw being that chainsaw is generally the most expensive part on a chainsaw milling system. 3/8 lo pro chain takes a very slightly thinner cut (around 15% to 20% thinner) than the larger standard 3/8 chain. This allows a smaller powerhead to drive a longer bar. PROS Faster milling speeds Smaller kerf lost as sawdust Longer bars can be used on smaller chainsaws without straining the powerhead CONS Lo pro ripping chain will suffer more chain stretch than standard 3/8 ripping chain Stay sharp ability is reduced due to smaller area doing the cutting Lo pro ripping chain is not as strong as standard 3/8 ripping chain - more chance of snapping particularly if abused Who makes 3/8 lo pro ripping chains? Oregon makes 91R - good for small chainsaws but not suitable on larger set ups. Stihl makes 63PMX which is an excellent chain which gives superb performance straight out of the box and works well on larger set ups. Granberg adapted 3/8 lo pro ripping chain is made from a Carlton chain and also provides good strong performance. . Differences between various manufacturers ripping chains There are no concrete answers to this question. A little like which chainsaws are the best Stihl or Husqvarna. Suffice it to say if one was far better than the other then everyone would use the same chain. But they do not and really it is simply a case of which one you think works best for you. . Sharpening Technique and best practice Within normal chainsaw use sharpening is one of the most important aspects of using a chainsaw. In chainsaw milling it becomes crucial. There is nothing new to be learned except to reinforce the basics of - consistent tooth length, consistent angle, correct chain shape, correct depth gauge setting. Just getting one aspect wrong can slow your chainsaw milling to half the speed you could be going. Quickly touching up a chain and chainsaw milling will cause poor results. Most people would benefit using some sort of fixed guide that controls tooth length. File size and where it is placed against the tooth controls the side plate angle and shape of the tooth. All chain sharpening principles remain the same - only the angle is different. https://www.youtube.com/watch?v=nMYnxtCYW8g

- 6 replies

-

- 4

-

-

- chainsaw milling

- chainsaw mill

- (and 6 more)