-

Posts

1,415 -

Joined

-

Last visited

Content Type

Profiles

Forums

Classifieds

Tip Site Directory

Blogs

Articles

News

Arborist Reviews

Arbtalk Knot Guide

Gallery

Store

Calendar

Freelancers directory

Posts posted by wyk

-

-

Like you say a decent high performance oil should be used but fuel/consumption is irrelevant as it will still be using 50/1 whatever the consumption is.

However good oil doesn't always mean expensive is best and the most suitable.

We all have our favourites and dislikes one way or another that's not to say whos right and whos wrong but the best oil is the one that doesn't seize the saw up

Fuel consumption is VERY relevant. If your saw uses 25% less fuel per revolution/amount of work than previous saws, it is also getting 25% less oil every time that piston goes up and down. This means if you run your new 25% more fuel efficient saw at 50:1, the piston and cylinder are seeing a ratio of closer to 65:1 compared to your old saw.

-

Yeah, Bitch! MAGNETS!

As the RPM's climb, the amplitude of the wave that triggers the system to fire increases, thus advancing it. It is built in to the ignition system design(whether saw or bike, etc). Thus, the saw is easier to start at lower RPM, and has the advance it needs at higher RPM. I know Husky have been more aggressive with their ignition advance lately, and I find little benefit adding ignition timing to most newer Huskies with limited coils. I have assumed Stihl were pursuing something similar, as I have been told advancing the ignition on MT saws is of little benefit.

And, to be frank, I feel ignition advance is really only needed if you have a GTG saw, or are competing. In the field, I prefer no modified advance.

[ame]

[/ame] -

Does it definitely control the advance at different points in the rev range ? If you had a saw and the auto packed up and you could salvage it with a £20 ebay Zama or buy a £200 dealer only part to replace it which would you do ? Lots of people spend money hacking the software on their cars, are they all stupid ?

I was quoted 100 quid for a 241C MT carb today.

-

Not all Americans are clever it seems...?

Seems silly, like buying a Tesla S and swapping the electrics for a small block V8?

I would hardly call the current generation of MTronic and Autotune comparable to a Tesla S...

-

9t .325

You still running like a 16" bar or sumfin? If I had a ported 562, I would be running it with a 20" bar and 3/8 chain. My 43cc saw runs a 16" 325 bar.

-

Lucky man, wages in Ireland must be good:sneaky2:

It was a long time ago since I was there but found the pizza place - they did a weird one with stewing steak on it, it was rather good in a strange sort of way.

When I was there, the Madeiran Wine Rally was on and they sponsored a Fiat Cinquecento rally car that was a right laugh, not quite as fast as the factory Celicas and Impretzas!

This is the place -http://www.tripadvisor.co.uk/Restaurant_Review-g189167-d1567707-Reviews-Pizzaria_Xaramba-Funchal_Madeira_Madeira_Islands.html

HEre's a pic I took tonight:

Got good reviews still:thumbup:

I make very little. I'm not even on holiday. I'm here on family bidniss. I am the red-headed step child, but the only family member in Europe. So, when they need to check out things here(real estate and attorneys in Portugal lately), they send me in. So here I am. It's a tough job, but someone has to do it. Personally, I prefer to be in the woods cursing the weather.

As for yer pizza, that place is not far from me. I was about 1km away from it earlier today.

-

Is that the island of Medeira in the Atlantic, home of the temperate climate with those channels that run down from the mountain top to irrigate the land...levadas, that's it:thumbup:

If you are anywhere near Funchal, try the pizza place on the left side of the town facing the harbour, forget the name but it was pretty good:thumbup:

You get about!

Spending most of this week in Funchal. Leaving tomorrow morning for Ireland, though.

Madeira is Portuguese for 'the wood', btw.

-

Never had any chrome coming off any of my tools but most date back to my teens when tools were made to last - paid for themselves thousands of times over:thumbup:

Anything made cheaply is not likely to last.

Tools are made out of steel. Steel can vary wildly in it's manufacture, treatment, and resultant fit for purpose.

Tools made of high carbon steel are generally finished in chrome plating to defend against rust. High carbon steel can make very robust and long-lasting tools. When plated correctly, they will last a lifetime. I have and use ProTo brand USA made tools that are older than many of the members on this board, and are still nice and shiny with chrome.

Saying your steel is chrome vanadium itself doesn't necessarily mean the tools are better, A La Teng. Chromium and vanadium have been used in steel for quite some time. Very few tools would not have some of each in their steel. They add hardness and elasticity when tempered correctly.

Just because the tool isn't shiny, doesn't necessarily mean it is not chrome plated. You can still bead blast chrome or give it a brushed appearance. In fact, it is far cheaper to manufacture them this way as polishing takes more time and QC.

All in all, how a tool is manufactured and treated is far more important than whether it is chrome plated or not.

On the right is a Teng socket I had lathed down to fit the carburetor flange on newer Stihl chainsaws. We'll see if it rusts...

And to keep this on topic, this is what's on my bench today. I am currently in Madeira, Portugal.

-

-

-

Does swapping out the winter shutter make a difference? Does it idle fine? Does it bog? Is the oiler working fine? What exactly is it doing?

-

The best advice you've received so far was to not buy a saw.

The second best advice is you already have a small saw, and you have no need for smaller, so go big.

But, since you ave no need for a big saw, see advice #1.

What I am suggesting is something affordable to replace the saw you have, to do the work you have been doing normally, as it appears to me that what you want is something new, not necessarily something you need.

Happy new year!

I have a Makita 4601 which is my only saw.It's 46cc so buying something similar seems a bit pointless after all the advice I've been given.

So I'm either gonna have to go for a micro saw for the reasons stated (nifty little carry aboot jobbie) or sod the practicality and go big.

I don't need a pro saw so if I don't go tiddler I'd go big and then put a smaller bar on the Makita for light duties.

Still undecided, but if go big it'll be a 365 Husky or a Makita/Dolmar 65-90cc beastie.

I have a lot of overgrown hedging I intend to cut back but I don't know whether a bigger saw to mash the lot would be better or a little tiny saw to chip away slowly. I suspect the latter.

-

-

Now I am going to imagine a brummy accent every time I read one of Eddy's posts.

-

For an all around saw like the OP seems to need, I don't see any reason why the current 50cc options won't suit him.

-

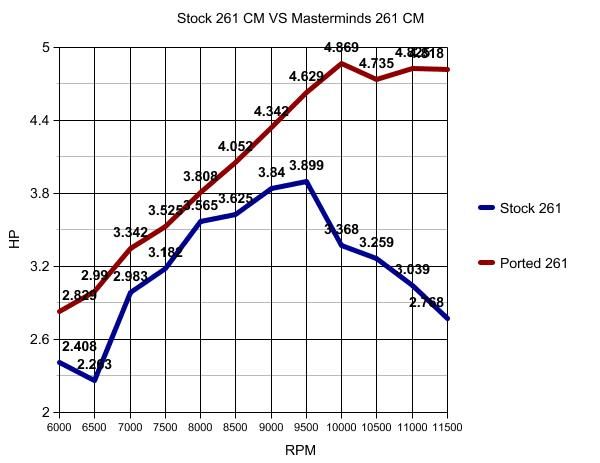

A 361 is lighter and handles better. But the 362CM is stronger. And with just a MM and timing, becomes a very strong saw.

-

Right, my verdict is it spits some chip out! It's hard to say if it was worth it, maybe for racing, but the effort required when it'll be used for day-to-day cutting, I highly doubt!

I do it on all my big bars. Not just for a bit quicker chain, but more for plunge or boring cuts. It makes the cut much faster and far less vibration.

Not as drastic an effect on larger bars, but you can see how it would cut down on the vibration.

-

50-60ft Scott's is what I've been on last few weeks, thinning and converting in to 3m lengths. Average dbh is around 15" and the husky 560xp with a 15" is noticeably quicker felling than the Ms 261's I'm working along side with the only problem is by 3 pm you start to wish it was a 261 whilst snedding.

I did nearly buy a 550 xp because of this but decided to man up and keep on with the 560.

441 or any 70cc saw is absolute overkill imo on these size soft woods... Would not touch one until the dbh is at least 20" and then I would still have the 560 for snedding.

I run a ported 50 or 40cc saw in such wood.

-

Tell that to the EPA:sneaky2:

Seen a few saws that have had modded Strato systems, I can fully see the logic and gains to be made but TBH, it is a massive step to take with anothers work saw and if it goes wrong.....................

It is one thing to get gains and another to get a steady idle and decent top revs, especially on an autotune!

I guess we are looking for a machine that is near scrap that doesn't have much cash owed on it of much love left to give it:001_rolleyes:

Here we go again..................

Here we go again..................Many strato mods have to do with defeating the strato system. I'm not a fan of this myself.

Mitch's mod only partially blends a small amount of mix in with the strato charge, and it only really starts to do so at higher RPMs.

-

I'm keeping it as a strato saw

That is still a strato. It only partially blends the mixes instead of defeating the strato entirely. The difference is impressive.

-

Just sayin...

-

It is bad enough bring blamed for my own mistakes let alone yours Wes:sneaky2:

Spud butchered the diaphragm gasket during the tear down. I'll have a new one tomorrow mebbe.

-

I accept your point about LP being taller than RS - its very noticeable if you put them side by side and explains why Stihl recommend a smaller (5.2mm) file for 3/8 chain.

However LP and LG are both round ground chisel and it must be difficult to grind the LP's drivelink down with the raker in the way.

They likely wouldn't be doing the bumper link by hand. In any case, if it is bothersome, use a non bumper chain...

-

Here's the difference. This is standard 325 vs race 325:

Stock:

Race:

372xp

in Chainsaws

Posted

My last sentence should have read:

" This means if you run your new 25% more fuel efficient saw at 50:1, the piston and cylinder are seeing an oil ratio of closer to 65:1 compared to your old saw".

The mix itself may be the same, but the amount of oil reaching your engine is significantly less. And I think it is beginning to show in the types of failures I am seeing in these saws. Saws have always seized or had other lubrication issues. I am not so sure why there would be a need to chance it any further and lean out the ratio ever more except to please the EPA, et al. But, as I have said before, it's your saw, it's your prerogative.