-

Posts

15,009 -

Joined

-

Last visited

-

Days Won

8

Content Type

Profiles

Forums

Classifieds

Tip Site Directory

Blogs

Articles

News

Arborist Reviews

Arbtalk Knot Guide

Gallery

Store

Freelancers directory

Posts posted by spudulike

-

-

I have never seen damage caused by carbon. I have seen partially blocked exhaust ports, even had a saw not making it over TDC caused by a lump of carbon on the squish band but not seen damage that would cause this sort of issue.

My thinking is it will either be a big air leak caused by component failure or a mix of slight air leak, saw a bit lean, possibly dirt or leak in some part of the fuel system.

This is my experience with these sort of issues.

-

1

1

-

-

Yup, a bit of a mess. One thing to add to my original thinking that seizure may have been caused by the impulse coming off is that the fuel lines on older 372s can wear through and leak air in to the fuel line causing running issues.

What I am saying is.....make sure the fuel system is checked over and a vac/pressure check is done after repairing the damage and tach tune the rebuilt saw to ensure good running.

Fortunately the 372 cylinder is pretty robust so can often be salvaged.

-

1

1

-

1

1

-

-

So little info, so much kit: -

Battery

Mains

Petrol

Size wood

Typical location of use...will determine power type

Budget

Operators experience

-

As he said but if you know a bit, I pull the plug out, get the piston at TDC, rock the flywheel to and fro and if the tappets don't move, you have the compression stroke which is the one you need.

Personally, I adjust the tappets by feel and you can get them pretty good this way.

One of the symptoms that the tappet gap is too big is that the engine gets very hard to pull over. This is because the large tappet clearance stops the automatic decomp system from operating correctly.

-

10 minutes ago, Stubby said:

I shot a couple of rats yesterday from my bathroom window whilst sitting on the can 🙂

Now there's a picture that will take days to get rid off!!

I do the rats round here, a decent air rifle and they don't like it up them.

-

1

1

-

2

2

-

-

You can look down the plug hole on some saws but forget the piston crown, drop the piston to BTDC and look at the cylinder bore above the exhaust port. I used this method as a very quick check and it is effective especially if you have a small head LED inspection torch.

-

1

1

-

1

1

-

-

Second what they said. The overheating suggests running lean leading to seizure. You should be able to tell lack of compression from pulling on the starter handle but removing the muffler should give you the full picture.

Most likely the impulse line has come off. I did a US ported one some time ago where this happened, the saw had destroyed its crank and shows that porting does protect the cylinder but the overrevving caused other damage.

-

1

1

-

1

1

-

-

Blimey!

-

-

The more open muffler and greater flow reduces heat faster and lowers the chance of seizing due to excessive heat so the ported saw runs cooler.

The bark box is a prime example of poor modification IMO (I have had the unfortunate experience to have heard a few), I always bounced the exhaust port shock wave off a muffler surface before exiting the muffler, that way you still get decent flow but also don't increase the noise excessively.

I preferred what I called "a rorty exhaust note" to "ear bleedingly loud", the ported saws I did were generally used in domestic and commercial work and any modification should be sympathetic to this use unless the customer states "forestry only" where decent ear muffs were needed.

-

3

3

-

-

You will probably get away with it for a bit as long as there is no major leakage. Any big leaks will cause the saw to run lean and that may well cause issues with seizure being the worst.

Choice is yours!!

-

-

That is what I meant, a "clip", section, page, extract of the manual assumes limit caps.

-

That there is the remains of a large shrub, not a tree. Just dig around it and pop it out with a wrecking bar and a lump of wood as a fulcrum.

Your neighbour sounds like a prize plonker who needs to get out once in a while.

-

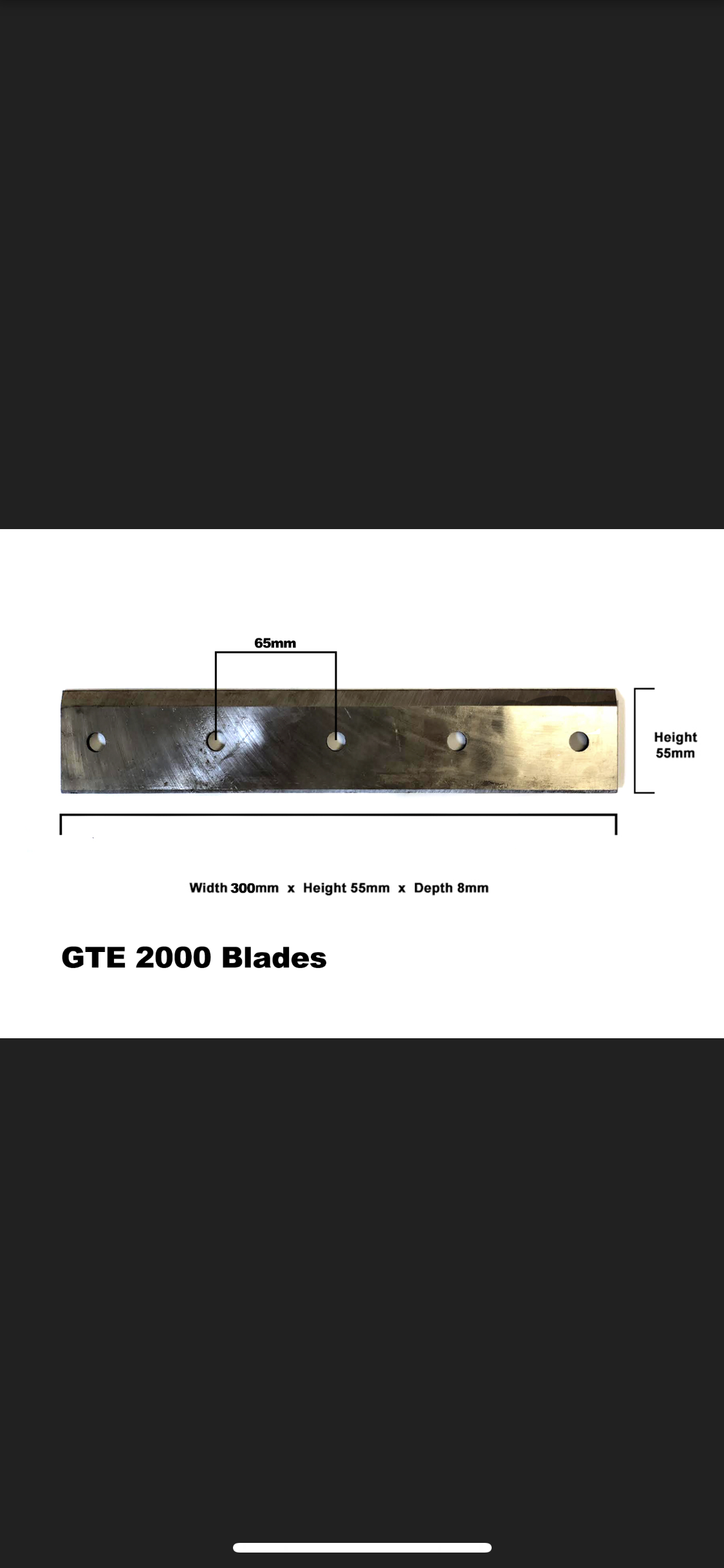

Are these the ones: -

GTS2000LTE Chipper Blades Set of 2 - Blacktools

WWW.BLACKTOOLS.CO.UK

Set of 2 blades to fit a black tools GTS2000LTE. -

6 hours ago, maybelateron said:

If you have a diagram of the blades dimensions and angles there are plenty of firms who can make them for you.

Probably the best suggestion and will probably be better than the Chinese ones.

I got some from [email protected] (JDnD Industrial Services) but it looks like they may not be trading now. I haven't used the blades yet but did test them with a diamond file and they were pretty hard matching their claims on being made from tool steel rather than mild steel or similar. Much cheaper than the originals as well.

There must be other small engineering companies able to make these blades, it is a pretty basic piece of engineering to them.

-

The clip assumes the limit caps are in place!

-

Neighbours, let them crack on at their expense.

-

Thanks for the update.

-

54 minutes ago, openspaceman said:

Okay before I take it all apart it looks like I need to get the intake boot off to look at the impulse line but suppose this means taking the cylinder off?

Noooooo, just look at the gap between the rear of the cylinder and the airbox with the top cover off. If the impulse has come off, you can use forceps to get it back on. The rubber may be a bit hard or even split. May be a good idea to replace it, go OEM as they are not expensive and better quality.

-

2

2

-

1

1

-

-

4 hours ago, openspaceman said:

Thanks to spud's link to the secondhand coil and flywheel I have it running with the coil.

It cuts well but takes a while to slow down to tickover once the throttle is released, any suggestions. First I will check if the butterfly is snapping shut but I wonder about an air leak.

I have a short video:

VID-20250206-WA0000.mp4 - Google Drive

DRIVE.GOOGLE.COM

VID-20250206-WA0000.mp4 - Google Drive

DRIVE.GOOGLE.COMwhich I will leave up for a little while

No problem, glad it is running after my input.

Have you looked at where the impulse line joins the bottom of the cylinder base. I once had three 260s in with their impulse lines disconnected, all in the same week.

Your bottom end sounds lean. If the L screw is set to 1 - 1.5 turns out and it is doing this, expect an air leak and the impulse is the most likely candidate.

Some of the old carbs are a bit iffy on the 026, if you do test it and this draws a blank, I used to get secondhand OEM MS260 carbs off eBay and use those....and charge the typical ebay cost of £25 to the customer....before some troll has a go, you know how it is!

-

1

1

-

-

Stihl Ms240 Ms260 Petrol Chainsaw Tested Ignition Coil & Flywheel 1121 024 026

WWW.EBAY.CO.UK

<p>Stihl ms240 Petrol Chainsaw </p><p>Tested ignition coil and flywheel </p><p>One fin missing on flywheel </p><p>Genuine used part</p><p>Please see pictures </p><p>All questions...-

1

1

-

-

Those aftermarket coils can be pretty crap at best. I think form memory, a lot of Stihls use the same coil and just fit other HT leads to suit different machines so perhaps a MS200T one would fit as the HT cable can be removed and swapped.

On the flywheel key, I would expect the magnets would align with the coil at around 10 degrees in advance to TDC. It is unusual for this to not be the case but have seen some strange exceptions up to 180 degrees out! The difficulty will be if the key has just slipped a few degrees out as it will be more difficult to find.

Again from memory, I think the 026 flywheel is removed by the screw in puller which makes pulling off the flywheel a breeze.

The 026 kill wires can rub around the top AV mount giving some annoying HT issues.

I usually try a second user OEM coil from the bay rather than the Chinese poop. More reliable.

-

1

1

-

1

1

-

-

Stihl 020T - 1996 - 2002

It was that good the MS200T was introduced which was petty much the same saw with some fancy transfer work and a new carb: -

2002 - 2012

and here we are some 13 years later.........still using the saws deliberating the best top handled saw......er...the fact that they are still very sought after speaks volumes.

New Firewood chopper

in Firewood forum

Posted

So, we are orange...Stihl & Husqvarna are both orange but there are some others that are orange and not so good.

Budget.....do you want new or old, if you purchase a knackered second hand one, can you fix it up? If not, you are needing new and a budget would sort out where you end up.

Pine trees....8", 12", 15"...3'? I ask as you will really notice the difference between using a 50cc saw and 70cc saw after the first hour or so. If most of your stuff is 1' and under, a 50cc saw will do the job just fine.