-

Posts

1,104 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Classifieds

Tip Site Directory

Blogs

Articles

News

Arborist Reviews

Arbtalk Knot Guide

Gallery

Store

Calendar

Freelancers directory

Posts posted by lux

-

-

This is the pilot core tool they don’t supply , well from where I hire it anyway. For hard going ground. Driven in by the post knocker and rotated out on the t bar using a fence post to lever it around. Takes a 50mm core.

Poking the ground with a fencing bar is just for seating the post upright to start off.-

2

2

-

-

They advise making a pilot hole first with a bar

They might advise it but like I said. It doesn’t come with it on hire. -

Hired the Australian one with the Honda engine a few times.

On the right ground it’s fantastic. On the wrong ground it’s miserable.

Sand with an almost sandstone compacted layer about 200 to 300mm below the surface was grim.

They don’t hire the spike out to pilot hard ground sadly.

On other ground 4 inch stakes have flown in no bother.

On the whole it’s a good bit of kit.

Hard on the ears though. -

Only ever used cobra but always found it easy to install in either static or dynamic applications.

To be fair it’s what they sell at the local arb shop so that’s what we use. No issues with it though. -

You don’t think you’re contracting yourself?

You won’t sell logs as the margins are too tight but those that do sell them are being greedy?

There’s a serious disconnect going on here.

Exactly what I thought as I was reading that …. Total contradiction.

How strange the margins seem tight when you don’t charge enough …-

1

1

-

-

-

I have a Hilix with an auto gear box. I live in Norway and as the rumour goes, it does snow and get cold here.

I tow chippers and trailers with a tracked chipper on quite a fair bit. The only problem I’ve had was losing it on sheet ice one day, trying to get up a long incline. Ended up about 40 metres back down the hill, jackknifed and the trailer/chipper combo down an embankment and the hilix stuck in a snow bank.

Going down hill, either click the gearbox into semi and keep to 1 or 2 gear. Or even easier hit the DAC button (Downhill Assist Control) and let the engine do the work for you.

I don’t think auto or manual would of made much difference there eh …. Glad to see although it must have been a bum clenching moment and a pain to sort nothing looked too damaged. Hopefully you were towed out without a problem.

Can’t remember the name of the program but there used to be a series following the recovery trucks is snowy Norway.

Was pretty good viewing.-

1

1

-

-

Merrist Wood in Guildford would be your best bet.

No, not too late but factor in the wage dip as a trainee again.

Do a distance learning course after getting your practical qualifications that will gear you for the second half of your career as perhaps a consultant doing surveys or tree officer for local authority. -

I heard that (in the UK at least) they're are significantly tax incentives for knocking down/rebuilding compared to renovation. How true it is I don't know

Much cheaper. It’s exactly what I’ve done.

For a start you can reclaim your VAT

-

1

1

-

1

1

-

-

A quick question. I tow regularly with the Ranger (manual) and on the hills can use engine braking to save cooking the truck brakes.

I've driven auto cars but not really had any real weight in the load.

How easy is this in a auto?

Asking as I'm looking to upgrade and there are a few auto versions available. Mitsubishi and Isuzu.

Any downsides to be wary of? Cooking the auto fluid??

Cheers

Most modern autos can be used in semi auto fashion these days and you can hold a gear like a manual. Have a look at what trucks offer an auto box you can do that with.

Good advantage with an auto is they generally have a higher torque rating than the manual equivalent and less chance of wear and tear pulling away / clutch slipping etc etc.

I know of one chap with the old style Isuzu rodeo auto that tows a digger everyday on auto

He was at 215k miles at that time with nothing but oil and filter changes to the auto box. Impressive.

If I was changing my hilux now which I’m not but if I did I’d certainly get auto next time.

-

4

4

-

-

Ask some private landowners. I’m sure you’ll find something local easy enough

-

Well I fitted the Stihl bar but without the two bar plates, I had to make a spacer for the rear stud nut from a 14mm AF nut.

Now i wonder if a 1980ish Husqvarna 2100 had a chain catcher fitted @adw? I don't feel comfortable using a saw without one nowadays. This saw only got through one bar when i stopped using it as it was damaged and I preferred the 084.

Really wouldn’t worry about those chain catchers. They make so little difference they aren’t worth replacing

-

1

1

-

-

Tbf there is a big difference between sizing in some brands

Not tried pfanner boots yet, they look so bulky for climbing.

It’s always the soles that fall apart long before the boot itself which is annoying. 12 to 18 months of climbing and the soles disintegrate on all Arb Boots.

I love the fit and comfort of the Andrews boots but the soles aren’t very long lasting -

The bearings are the weak points but I think the weakness is really the owners running them till death rather than greasing them up once in a while. They have their little foibles but once you have fixed a couple, they are pretty simple and save a lot of time and trouble doing smaller tree work. Not sure anyone round here likes fixing them though.

Have to say mine have been bloody good.

Keep on top of the valve clearances and I’ve found them reliable.

Daily greasing on hedge cutter heads in the trimming season has kept them sweet.-

1

1

-

-

Is the 131 better than the current 135? [emoji848]

No difference in performance whatsoever . I’ve got both but don’t use the the new style shaft on them. Not so keen on the new saw heads either. Prefer the old one.

Trigger unit on the older 131 is better. Easier to lock it into a running position which is very handy doing tricky outstretched trimming jobs off tall step ladders etc. The 135 has to be put onto a high idle position on the choke to achieve the same. Just more of a faff but does the same.

The older style shaft fits them both meaning you can run all your hedge trimmer heads on them so that’s handy.

Both fantastic machines

-

I loved my positioner, but I would usually get less than 6 months out of one before it was slipping horrendously and I'd have to replace the clutch. Not a deal breaker for sure but annoying. I've not spoken to anyone else that's had the same problem though.

I moved on to a pinto/vt setup. Don't really notice the sitback and having the option to turn it into a secondary climbing system is super useful.

My lanyard is 7m long with the last 4m living in a hip bag

Same.

I don’t climb everyday so got longer out of the clutch but got through a couple. Nice device though. No real grumbles about mine.

Changed over to a Zillon but ran my own lanyard through it. Also a good bit of kit but can be easy to catch it and release some rope through just as you are getting into a work position. Quite happy with it though

-

-

It’s the best pole saw on the market.

Brilliant for big hedge trimming jobs too.

Got 3 on the go atm. Would bother with anything else [emoji106] -

N and j Aluminium

-

1

1

-

-

Day rate can be handy when you get an unusual job to price or clients that want you doing various tasks over a few visits and you know they will change their minds continuously

Set out what machines are included in the price or what extra they will be. As long as it’s all set out there is little chance for ambiguity.

In terms of staff / subbies I’ve always paid day rate.

No one has given me an hourly rate except on large machinery

Finishing times are swings and roundabouts, sometimes a day is done at 3 sometimes it’s 5. Generally it balances out but if it’s a lot of late Finishes a bit of extra cash smoothed things-

1

1

-

-

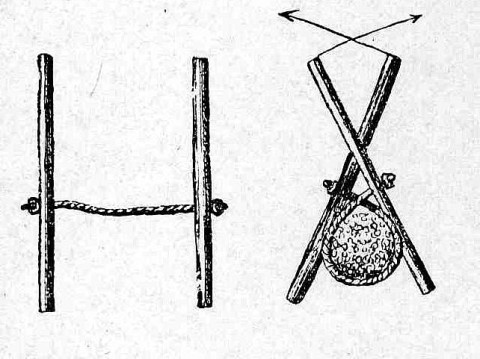

Ive made a few hazel faggots for firewood/kindling with a woodmans grips( just playing around.)

Faggot engine:

SADEIK.WORDPRESS.COM Bodgers’ Ball I: Pimps, faggots & benders | Wympole & Wratsworth

Bodgers’ Ball I: Pimps, faggots & benders | Wympole & Wratsworth

Last weekend was when the Bodgers' Ball happened so here is part one of what occurred... Ok, so the title grabbed your...

Some interest defintions here seems the terms are kind of interchangeable....

A faggot, in the meaning of "bundle", is an archaic English unit applied to bundles of certain items. Alternate spellings in Early Modern English include fagate, faget, fagett, faggott, fagot, fagatt, fagott, ffagott, and faggat.

Sometimes called a short faggot, a faggot of sticks equals a bundle of wood sticks or billets that is 3 feet (90 cm) in length and 2 feet (60 cm) in circumference.[1] The measurement was standardised in ordinances by 1474.[1] A small short faggot was also called a nicket.[2] A brush-faggot (sometimes shortened to brush) was a bundle of similar size made of brushwood.[3]

A long faggot of sticks equals a bundle larger than 3 feet (90 cm) long. In a book on slang used at Winchester College fire-dogs were fire basket (andirons) that could hold long faggots, and half-faggots were smaller andirons that could only hold short faggots and were later converted for use with coal.[4]

A long faggot was also called a kidd faggot,[5] kid, kide, or kidde being Middle English for firewood in bundles.[6]

A fascine (or bavin[3]) is a type of long faggot which is approximately 13 to 20 feet (4 to 6 m) long and 8 to 9 inches (20 to 23 cm) in diameter and used to maintain earthworks such as trenches.[7][8][9]

A faggot was also a unit of weight used to measure iron or steel rods or bars totaling 120 pounds (54 kg).[1]

EN.WIKIPEDIA.ORG Faggot (unit) - Wikipedia

Faggot (unit) - Wikipedia

Seems to be a lot of variation on the use.

On the woodlands tv channel a local guy in Petworth makes the pimps for fire lighters in the same device as yours and it’s called a pimp machine there.

Faggots he is making are in long bundles for river banks.

Maybe the variation is regional ?

The temporary structure / shelter they use is known as a Bender

-

Faggot is also a ball of food with meat.

Faggots, pimps and bavins were all coppice products.

Both Faggots and Fascines are used for river bank erosion

Pimps are for fire lighting. I bought birch pimps from a garden show once. I have to say they were outstanding fire lighters. Way better than the fire lighter blocks.

A mix of super fine twigs to light easily bundled in with some nice kindling to get heat going. Excellent.

Gotta love the old terminology.

A dozen faggots and a few pimps please my good man ..

-

Anyone got a contact for a supplier of stakes and rods for riverbank stabilisation?

Looking for faggots Doobin.

Look on coopice-products.co.uk

You’ll find a list of suppliers/ makers on their mate. -

I agree with @joenewton

The crux of this one seems to be an experience / confidence issue.

I can think of plenty of trees you really have to push yourself mentally on to get past it and improve.

Worst thing about small leaning trees like that if there is usually they are more tiring / uncomfortable getting into good working positions.

Spend time setting up though. Try not to make cuts from awkward or strained positions

Any pictures of the tree. ?

What is problem here??

in Tree health care

Posted

No suppose about it John. He is right.

I don’t want to kerb your enthusiasm but it’s the old saying of don’t run before you can walk.

Those are basic idents in the picture and having some knowledge of diseases / decay in combination with the characteristics and properties of the host species is what will enable you to make informed decisions on if it’s safe to climb or if you need to have an alternative plan

Reading books and using the internet is handy but really needs to be in conjunction with formal training or a knowledgeable tree surgeon who’s willing to pass on their skills and knowledge

Get someone in and offer to help groundwork for them. You’ll learn a lot more than having a go at it yourself

If they are really rotten you’ll probably end up breaking something or worse still yourself.

Stay safe.